I was recently contacted by Lowell Thomas Inc the company behind the Jackclamp and fast forward to today, I have a couple of their JackClamp’s in my hands so that I could provide my personal feedback on them. So what are JackClamps? Simply put, they are ratcheting bar clamps, but not just any ratcheting bar clamps, these are on steroids and have evolved/mutated to incorporate an extra “arm” or bar for additional configurations and use such as the ability to use them as a jack and for hoisting, and they’re made in the USA which is always a plus. According to the Manufacturer these can:

I was recently contacted by Lowell Thomas Inc the company behind the Jackclamp and fast forward to today, I have a couple of their JackClamp’s in my hands so that I could provide my personal feedback on them. So what are JackClamps? Simply put, they are ratcheting bar clamps, but not just any ratcheting bar clamps, these are on steroids and have evolved/mutated to incorporate an extra “arm” or bar for additional configurations and use such as the ability to use them as a jack and for hoisting, and they’re made in the USA which is always a plus. According to the Manufacturer these can:

- Clamp safely and securely with no slipping

- Jack and hoist up to 300 lbs

- Spread gaps as small as 1/4″ with the spreader attachments

- Clamp irregular (even round) shapes with the v-jaw attachments

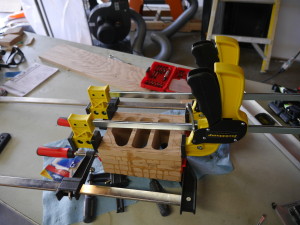

My first impressions with these: out of the box it came with 2 JackClamps with a bunch of accessories including a couple of v-jaw attachments, a couple of foot attachments, and a couple of spreader attachments. Looking at the JackClamp, at first glance it seemed like any ordinary ratcheting clamp but under a further inspection it was hard not to miss the additional bar on the top of the clamp. The additional top bar is removable and reversable and so is the is the main bar at the bottom and these give you all sorts of possibilities such as more options and flexibility when clamping and you can also get very creative and start using it for as a spreader with or without the spreader attachments or as a jack. The build quality is good and feels very solid as they used thick heavy duty plastics for the frame and the metal used for the bars was a hefty 1/4″ thick. I own a few Irwin quick-clamps and Harbor Freight ratcheting bar clamps and these are definitely a step up in terms of build quality. They also include a pair of levels similar to how old school drills used to have built in levels to keep your work plumb.

When it comes to their clamping strength, these are definitely stronger at clamping than my Irwin’s, and HF ratcheting bar clamps. In contrast the Irwin’s offer good clamping force and the HF ratcheting bar clamps are very weak and I stray away from these unless I don’t need much clamping force on a certain project. These JackClamps offer the best clamping force I’ve tried on any ratcheting clamp up till today, although they are not the best in terms of raw clamping force in general. Just to put their clamping performance into perspective, they cannot compete with less expensive low duty traditional bar clamps in terms of raw clamping force. A while back I was working on making a bandsaw box and after I had cut out the drawers and wanted to clamp up the side openings in the frame, I wanted to use these JackClamps for this job and although they offer superior clamping force as ratcheting bar clamps, they simply did not have enough force to clamp the side openings of the frame to my satisfaction. They were capable of closing the openings and gaps, but not tight enough to minimize the joint to my liking. So I ended up using my HF traditional bar clamps which were able to tighten down much further that was possible with the JackClamps. But head to head with other ratcheting bar clamps, these are easily superior. In other projects, as I clamp down tightly with the Irwin’s or HF ratcheting bar clamps, when I tighten as much as possible they reach a max tightening range where they plateau and putting extra pressure beyond that, will cause them to slide back on the bar because they simply cannot tighten beyond a certain point. This sliding is very noticeable when I apply much force on my HF ratcheting clamps making them very weak in comparison. The Irwin’s don’t fare as badly as the HF ratcheting bar clamps but still exhibit this trait, and the JackClamp’s exhibit the least amount of slipping when tightening beyond the max, almost non-existent. This allows the JackClamp’s to grip much tighter.

When it comes to their clamping strength, these are definitely stronger at clamping than my Irwin’s, and HF ratcheting bar clamps. In contrast the Irwin’s offer good clamping force and the HF ratcheting bar clamps are very weak and I stray away from these unless I don’t need much clamping force on a certain project. These JackClamps offer the best clamping force I’ve tried on any ratcheting clamp up till today, although they are not the best in terms of raw clamping force in general. Just to put their clamping performance into perspective, they cannot compete with less expensive low duty traditional bar clamps in terms of raw clamping force. A while back I was working on making a bandsaw box and after I had cut out the drawers and wanted to clamp up the side openings in the frame, I wanted to use these JackClamps for this job and although they offer superior clamping force as ratcheting bar clamps, they simply did not have enough force to clamp the side openings of the frame to my satisfaction. They were capable of closing the openings and gaps, but not tight enough to minimize the joint to my liking. So I ended up using my HF traditional bar clamps which were able to tighten down much further that was possible with the JackClamps. But head to head with other ratcheting bar clamps, these are easily superior. In other projects, as I clamp down tightly with the Irwin’s or HF ratcheting bar clamps, when I tighten as much as possible they reach a max tightening range where they plateau and putting extra pressure beyond that, will cause them to slide back on the bar because they simply cannot tighten beyond a certain point. This sliding is very noticeable when I apply much force on my HF ratcheting clamps making them very weak in comparison. The Irwin’s don’t fare as badly as the HF ratcheting bar clamps but still exhibit this trait, and the JackClamp’s exhibit the least amount of slipping when tightening beyond the max, almost non-existent. This allows the JackClamp’s to grip much tighter.

One thing my other ratcheting bar clamps can’t do is to be able to remove and reverse the main bar allowing them to be used for spreading. This is because they use a pin at the end of the bar that prevents the bar from being removed. This pin doesn’t exist on the JackClamp’s thus allowing the bar to be easily removed and can also be reversed so we can use them as spreaders or as jacks or as hoists. On a recent project, I had to take apart an old custom made cabinet that was held together by nails so that I could salvage the wood. I was able to use this JackClamp as a spreader to spread apart the side panels forcing the frame pieces to come apart from each other cleanly. The JackClamp is also able to go a step further at spreading thin gaps wide open with the use of the additional spreader attachments. These attachments are able to fit into gaps as small as a 1/4″ wide to spread them even further. I tried this out also while taking apart the old cabinet and the JackClamp’s were quite useful in this regard. Also not available on regular ratcheting clamps are 2 bar configurations. I was looking at the JackClamp documentation and on one side of the sheet is a list of all the available configurations and one of them was a two clamp configuration where you use two trigger grips on one bar for both clamping and spreading or clamping and jacking.

One thing my other ratcheting bar clamps can’t do is to be able to remove and reverse the main bar allowing them to be used for spreading. This is because they use a pin at the end of the bar that prevents the bar from being removed. This pin doesn’t exist on the JackClamp’s thus allowing the bar to be easily removed and can also be reversed so we can use them as spreaders or as jacks or as hoists. On a recent project, I had to take apart an old custom made cabinet that was held together by nails so that I could salvage the wood. I was able to use this JackClamp as a spreader to spread apart the side panels forcing the frame pieces to come apart from each other cleanly. The JackClamp is also able to go a step further at spreading thin gaps wide open with the use of the additional spreader attachments. These attachments are able to fit into gaps as small as a 1/4″ wide to spread them even further. I tried this out also while taking apart the old cabinet and the JackClamp’s were quite useful in this regard. Also not available on regular ratcheting clamps are 2 bar configurations. I was looking at the JackClamp documentation and on one side of the sheet is a list of all the available configurations and one of them was a two clamp configuration where you use two trigger grips on one bar for both clamping and spreading or clamping and jacking.

To aid the use of using this JackClamp as a jack, they offer the additional foot attachments so that the JackClamp can rest sturdily on the floor when jacking. The foot attachment allows the clamp to stand up on it’s own although the foot attachment isn’t very sturdy or stable on it’s own. They seem to be designed for use with 2 JackClamps at a time, each with a foot attachment to to compensate for the lack of sturdiness on each foot.

As for it’s hoisting capabilities, I wasn’t able to test out this feature but it does seem to be well made for this activity. The second bar comes in very hand for this and has a hole at the end of the bar so the clamp can hang and lift weight upwards.

Another neat feature with these clamps is the ability to clamp onto surfaces that aren’t flat, for example round pipes, and this is thanks to the included v-jaw attachments. I wasn’t able to test these out but they will help you out if you ever find the need to hold and clamp pipes for let’s say welding or drilling into those said pipes.

Another neat feature with these clamps is the ability to clamp onto surfaces that aren’t flat, for example round pipes, and this is thanks to the included v-jaw attachments. I wasn’t able to test these out but they will help you out if you ever find the need to hold and clamp pipes for let’s say welding or drilling into those said pipes.

One negative I found with these clamps, is that these clamps appear to come in only one size. I found that the clamps I received can only open and clamp as wide as 14.5 inches. Sure there are plenty of projects that can be done with this range, although there are plenty of projects that it can’t if you need to clamp something thicker than 14.5 inches. There were a few projects I had in mind where these clamps had to sit in the sidelines while my other larger clamps fit the bill simply because of the limited clamping range of the JackClamp’s. These clamps are good for small to medium projects, but it would be nice to see larger models of these clamps to fit larger projects and also smaller clamps for small clamping needs.

Final thoughts: these JackClamps were very interesting after all and I can easily see that a lot of thought was put into designing and engineering these ratcheting bar clamps. They’re sturdy, well built, have strong clamping force and are the swiss army knife of clamps. These clamps can almost do it all like a Jack of all trades, but at the same time a master of none. In terms of ratcheting bar clamps go, I can’t think of any better and these easily outperform other ratcheting bar clamps I’ve tried, although they simply cannot keep up in terms of serious clamping force compared to traditional bar clamps. These JackClamps are very useful for a large variety of applications, not just clamping, such as jacking, hoisting, and spreading. Although at it’s current size, it’s limited to only small to medium sized projects when it comes to clamping and because of this I would like to see larger and smaller JackClamps so it can fit a full range of clamping needs. Long story short, these are some very damn good ratcheting bar clamps offering the best performance I’ve seen in their category plus the extra attachments and extra bar make use for some interesting applications that your other clamps simply cannot do.

Leave a Comment